The way in which the nuclear sector expands over the next decade will determine whether the United States can unlock the promise of reliable, low-carbon power at a competitive cost. We stand at a turning point. If we simply allow market forces to dictate outcomes, we risk repeating the mistakes of the past—spiraling construction costs, supply chain bottlenecks, and missed opportunities for innovation. But if we take a mindful approach, we can create an enabling environment that allows small and medium-sized enterprises (SMEs) to participate meaningfully in nuclear’s scale-up. Doing so is not only smart industrial policy; it is an essential strategy for beating the “cost curse” of nuclear power. We know from prior experience that SME’s are more likely to provide new, innovative ideas than larger, more established companies, and that SME’s are often able to offer more competitive prices for those products for which they specialize in production.

Lessons From China’s Manufacturing Strategy

A recent article in Nature—“China reins in the spiralling construction costs of nuclear power — what can other countries learn?” (July 28, 2025)—offers striking evidence of what is possible when a nation invests in domestic supply chains. The authors highlight that between the 1960s and the 2000s, nuclear construction costs in the United States increased tenfold, and in France nearly doubled. In sharp contrast, China halved its construction costs by the early 2000s.

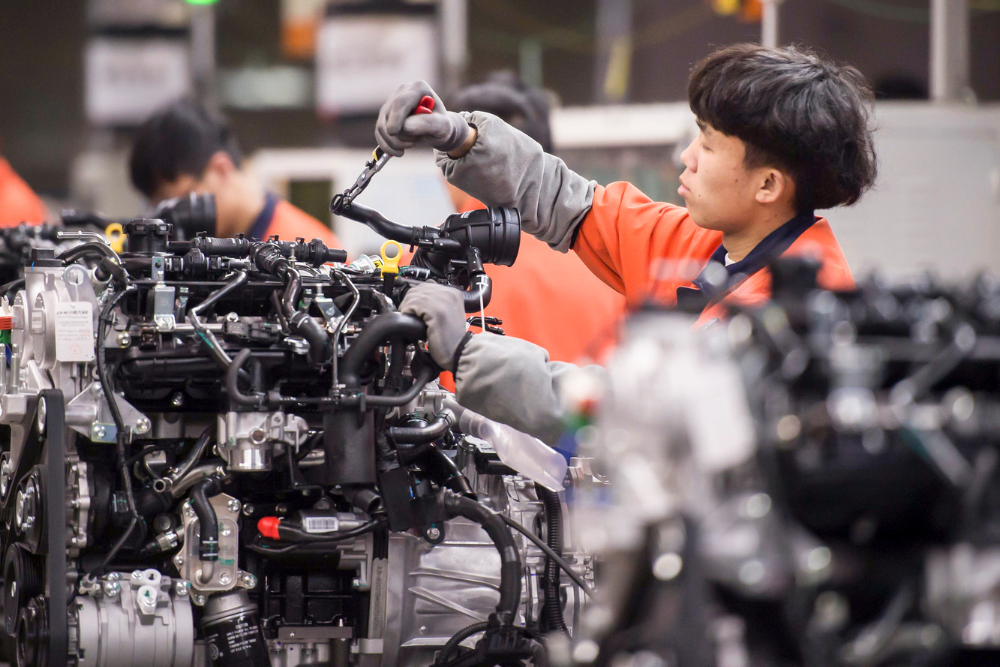

How? A central factor was China’s decision to re-shore conventional component manufacturing. By producing key nuclear components—such as tubes, ring cranes, and charging pumps—domestically, they reduced costs by as much as half compared to imported equivalents. This is a powerful lesson: controlling the supply chain and empowering local manufacturers can make the difference between prohibitively expensive nuclear projects and those that deliver affordable, resilient energy.

The Untapped Potential of SMEs

In the United States, the Department of Defense has long recognized the strategic role of SMEs in building resilient supply chains. Through targeted programs, the DoD has deliberately expanded SME participation in defense manufacturing, driving innovation while supporting nationwide economic growth. The same principle applies in energy—particularly nuclear.

SMEs are often the source of specialized expertise, agile production, and creative problem-solving. Yet too often, they become the weakest link in the supply chain, not because of capability but because of financing. SMEs rarely have access to the capital required to ramp up quickly. Without innovative financing mechanisms, they remain underutilized, even when demand is strong.

Financing the Full Supply Chain

In earlier writings such as “Financing America’s Nuclear Fuel Future,” I have argued that capital allocators must broaden their perspective when financing nuclear expansion. It is not enough to fund the anchor enterprises—the large companies building reactors or managing fuel. Financing must also extend to the supply chains that enable these projects, with particular attention to SMEs.

Imagine a financing model that accounts for the capital needs of the entire ecosystem. Such an approach would prevent the bottlenecks we so often see when critical but undercapitalized suppliers cannot keep pace. It would also accelerate the creation of robust, American-made nuclear supply chains capable of competing globally.

Policy Levers to Support SME Participation

Financial innovation in the private sector must be paired with policy innovation at the federal level. The Internal Revenue Code could play a meaningful role here. For example:

- Targeted tax benefits for SMEs engaged in nuclear component manufacturing, reducing their cost of capital and incentivizing investment in critical capabilities.

- Tax breaks for reactor owners that contract directly with SMEs, rewarding them for strengthening domestic supply chains and creating a multiplier effect for the broader economy.

These are only starting points, but they highlight the kinds of tools policymakers could use to ensure SMEs are not left behind as nuclear scales up. More will be said on this in future writings, but the principle is clear: federal policy should deliberately align with industrial needs to support SME participation.

A Window of Opportunity

The United States now has a rare window of opportunity to rethink its approach. As the nuclear sector ramps up, we can either leave SME participation to chance or deliberately design pathways for them to thrive. Choosing the latter will pay dividends—not just in reduced project costs, but in innovation, job creation, and industrial resilience.

Any supply chain is only as strong as its weakest link. If we want nuclear energy to succeed on cost, scale, and reliability, then supporting SME manufacturers must be a priority, not an afterthought. By enabling their participation today, we can build a nuclear future that is affordable, resilient, and unmistakably American.